The principle of MIM compaction-A

1. Definition of forming

Densify powder into green compacts with a certain shape, size, porosity and strength, the process is the MIM forming.

2. The importance of forming

1) It is a basic powder metallurgy process whose importance is second only to sintering.

2) It is more restrictive and determines the entire production process of powder metallurgy than other processes.

a) Whether the forming method is reasonable or not directly determines whether it can proceed smoothly.

b) Affect the subsequent processes (including auxiliary processes) and the quality of the final product.

c) Affect production automation, productivity and production costs.

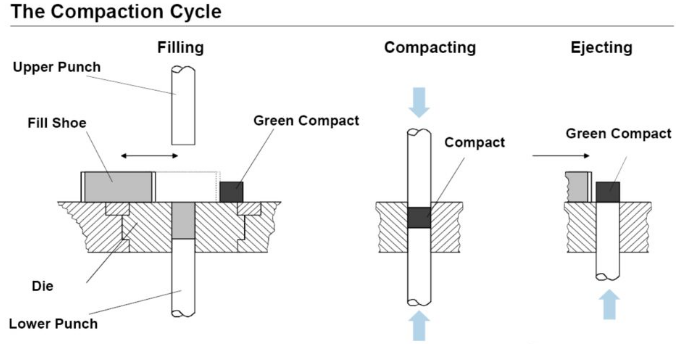

Compression molding is to load metal powder or powder mixture into a steel press mold (female mold), press the powder through the die punch, and after the pressure is relieved, the compact is released from the female mold to complete the forming process.

The main functions of compression molding are:

1. Form the powder into the required shape;

2. Give the compact with precise geometric dimensions;

3. Give the required porosity and pore model to the compact;

4. Give the compacts proper strength for easy handling.

Phenomena that occur during powder compaction:

1. After pressing, the porosity of the powder body is reduced, and the relative density of the compact is significantly higher than that of the powder body.

The compaction reduces the stacking height of the powder, generally the compaction exceeds 50%

2. Axial pressure (positive pressure) is applied to the powder body. The powder body behaves like a fluid to a certain extent. When a force is applied to the female mold wall, the reaction force-lateral pressure is generated.

3. As the powder is compacted, the density of the compact increases, and the strength of the compact also increases.

4. Due to the friction between the powder particles, the pressure transmission is uneven, and the density of different parts in the compact is uneven. The uneven density of the green compact has a very important influence on the performance of the green compact and even the product.

5. After the pressure is relieved and demoulded, the size of the green compact will expand-produce elastic after-effect. Elastic aftereffect is one of the main reasons for the deformation and cracking of the compact.